Enhancing Product Appearances: The Role of In-Mold Decorations in Manufacturing

Enhancing Product Appearances: The Role of In-Mold Decorations in Manufacturing

Blog Article

In-Mold Decorations Demystified: Opening the Secrets Behind This Advanced Production Refine

In today's fast-paced manufacturing landscape, in-mold decors have actually emerged as a sophisticated method that proceeds to intrigue sector professionals. This advanced production procedure holds the assurance of revolutionizing the way we view and use decorative aspects in numerous items. As we look into the ins and outs of in-mold designs, a globe of cutting-edge opportunities unravels, offering a glimpse into a realm where design meets performance in a seamless combination. In-Mold Decorations. Remain tuned as we explore the underlying principles and reveal the enigmatic appeal of in-mold designs, dropping light on the tricks that propel this process to the forefront of modern production techniques.

The Advancement of In-Mold Decorations

The development of in-mold decorations has been noted by considerable developments in technology and layout technology. In-mold designs were limited in their intricacy and color alternatives. With the development of new production methods and products, the possibilities have actually broadened significantly.

One trick development has actually been the advancement of high-resolution printing procedures that permit intricate styles with vivid colors to be moved onto items throughout the molding procedure. This has enabled makers to achieve photorealistic photos and comprehensive graphics that were formerly unattainable.

Additionally, the assimilation of robotics and automation in the in-mold decoration procedure has actually enhanced performance and consistency in using designs to items. This not just reduces manufacturing time but additionally enhances the general top quality of the finished products.

Recognizing the In-Mold Process

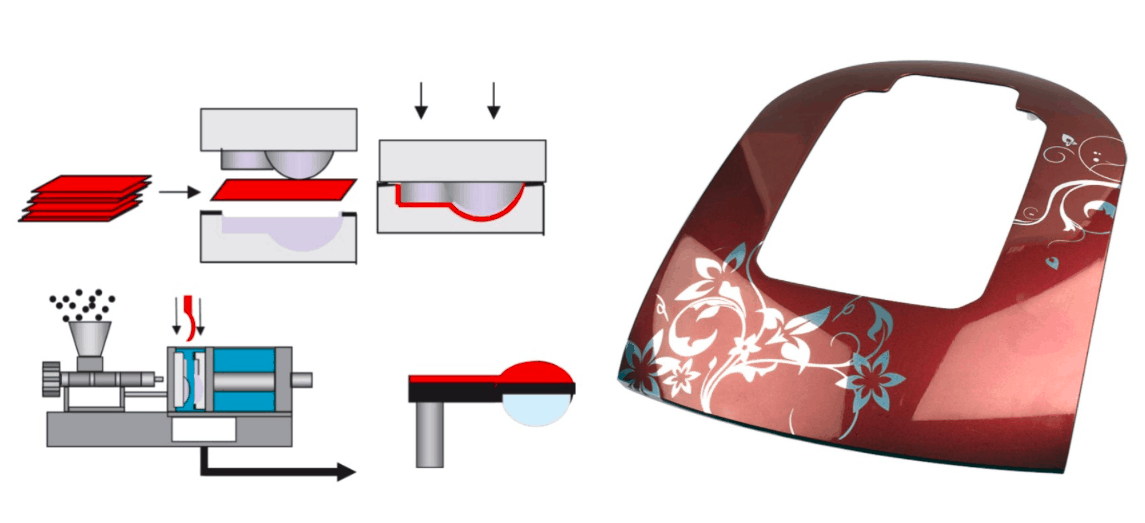

Significant by substantial advancements in technology and layout technology, the development of in-mold decorations has paved the means for a much deeper understanding of the detailed procedure included in producing these ornamental aspects. The in-mold process is a sophisticated manufacturing strategy where attractive components are integrated directly into the final item throughout the molding process.

Recognizing the in-mold process needs precise control over numerous specifications, including timing, pressure, and temperature level, to make sure the design sticks appropriately to the item. Additionally, picking the ideal materials is critical to accomplishing premium results. By grasping the complexities of the in-mold procedure, makers can produce aesthetically striking products with long lasting, long-lasting decors that enhance both the aesthetics and capability of the final item.

Benefits of In-Mold Decorations

Progressing item aesthetic appeals and sturdiness, in-mold decors provide a streamlined strategy to integrating attractive elements during the production process. One of the vital advantages of in-mold decors is the smooth integration of graphics, structures, and shades directly right into the item during the molding process. In-Mold Decorations. This gets rid of the demand for post-production decoration techniques, such as paint or printing, which can be taxing and costly

In addition, in-mold designs are extremely resilient as the graphics are enveloped within the item, making them resistant to wear, scratches, and fading. This leads to items that maintain their visual charm and branding for a longer period, even in extreme settings.

In enhancement to enhancing aesthetic appeals and longevity, in-mold decorations also provide enhanced style versatility. Makers can conveniently include detailed layouts, appearances, and branding aspects that would certainly be difficult or impossible to achieve with typical decor approaches.

Applications Throughout Industries

Throughout numerous markets, in-mold designs have found versatile applications that enhance both the visual charm and durability of items. In the auto field, in-mold designs are frequently utilized for interior trim parts, such as facility gaming consoles and door panels, supplying a high-quality coating that is immune to scratches and fading. The customer electronics industry advantages from in-mold designs on items like smartphone instances and laptop covers, where intricate layouts can be flawlessly integrated into the production process. Additionally, the device market utilizes in-mold decors to produce durable and elegant control panels and fascia for items like ovens and fridges. In the toy sector, in-mold designs are used to add vibrant shades and detailed graphics to plastic toys, making sure a child-friendly and visually attractive look. Generally, in-mold decors provide a cost-effective and effective way to boost the aesthetic appeals and longevity of items throughout a large range of industries - In-Mold Decorations.

Future Patterns in In-Mold Modern Technology

The evolution of in-mold decorations is positioned to proceed forming the landscape of product design and manufacturing as Future Trends in In-Mold Innovation assure innovative services to additionally enhance visual looks and item longevity. One of the key future trends in in-mold innovation is the advancement of innovative materials that use enhanced toughness and flexibility, enabling more intricate and detailed layouts to be realized. In addition, advancements in digital printing strategies are enabling manufacturers to attain higher modification and information in in-mold designs, try this opening up new opportunities for innovative product designs. Another substantial fad is the combination of wise innovations, such as NFC tags or LED lighting, directly right into in-mold designs, adding functional and interactive components to products. Furthermore, the fostering of eco-friendly materials and procedures in in-mold modern technology is ending up being increasingly crucial, as sustainability proceeds to be a driving force in the production market. In general, the future of in-mold technology holds great prospective for pushing the borders of style opportunities and improving the overall top quality of products throughout various markets.

Conclusion

In-mold decors have reinvented the production process by flawlessly integrating style components right into products. Comprehending the details of this process is vital for sectors wanting to improve their items with sturdy and visually appealing designs. With its many advantages and functional applications across different markets, in-mold modern technology is positioned to proceed developing and shaping the future of production. Stay notified and remain in advance in this cutting-edge field.

By grasping the see this here ins and outs of the in-mold process, producers can produce visually striking items with durable, durable decorations that boost both the visual appeals and functionality of the final item.

Progressing product looks and longevity, in-mold decors use a streamlined approach to incorporating attractive aspects during click for info the production process. One of the key benefits of in-mold decorations is the smooth combination of textures, graphics, and shades straight into the product throughout the molding process.The development of in-mold decorations is positioned to continue forming the landscape of product design and production as Future Trends in In-Mold Technology assure ingenious solutions to additionally improve aesthetic aesthetic appeals and item toughness.In-mold decorations have actually transformed the production process by flawlessly integrating style elements into items.

Report this page